Tuesday, April 28, 2015

Sunday, April 26, 2015

Thursday, April 23, 2015

Greenbelt Hybrid Calgary Spring 2015

This week, our Hybrid Calgary group has started the second

module of their Lean journey. Here are some photos of our participants doing

Gemba Walk and Value-Stream Mapping.

Monday, April 20, 2015

Japan Lean Tour Day 5 Report - Kyoto

Kyoto - I left my heart in Kyoto!

As I was voluntold (by Jake - San) with the honor of offering a blog entry about the Kyoto adventure I find it very difficult, without instead offering some other thoughts on the complete Lean Japan Tour.

I will offer the entry without an arranged order.

The Kyoto day trip was the icing on the cake or the dessert of the week. While the plant visits offered incredible insight, the Kyoto "walk about" (about 9 miles) allowed us to step into the true nature and culture of Japan. I need to state right now, for any that will take this tour in the future, you must take it as gospel, that when David says to wear comfortable shoes and to make sure you do not get separated from the group, he means it. Those I traveled with know I speak as one that twice did get separated from the group. Once to find my own way back to the arranged hotel and once by luck I re found the group. Without a small working ability to communicate in Japanese, I'd still be lost in Shinjuku.

In Kyoto our guide Miyuki - San offered a great deal of historical information. The city is an incredible blend of old, semi old, and new. New high rises abound, while in between you will view small many century old buildings with classical Japanese architecture. Yet the two worlds do not collide. They blend together and offer the visitor a unique insight into the Japan of the now and that of the very distant past.

The capping of for the day was a simply amazing traditional Japanese meal in a restaurant that offered the most memorable sunset I have ever been blessed to see. Yes Japan is called the land of the rising sun, but the sunsets are breathtaking. For the romantics I cannot state strongly enough how mesmerizing it was to behold.

The assembled group of participants come from many industries, yet there was an immediate common bond. Not only to help each other, but beyond that. Friendships were made. Business relationships generated. Now that I have had an opportunity to view the Lean Reflections site I see that other participants have offered detailed information on the other vista we under took. I cannot state strongly enough that if you ever get the chance to join on one of the Lean Tours grab the opportunity, hang on tight, get ready to learn and enjoy a life altering experience.

Regards

Michael J. Glukler

Japan Lean Tour Day 4 Report

Today's entry was submitted by Mr. Fabio Doninelli, a guest on our Executive Tour.

We boarded the bus at 8:40am.

During the trip comments were made from each member of the Blackbelt tour on Lean achievements in their own companies.

Then, the first stop of the day was Mitsubishi Electric.

After a short presentation we had a nice walkthrough of the facility.

Mitsubishi represented a Different type of facility so far: less of a mass production type of factory, more of a smaller amount production type of facility. Therefore more human labor was involved.

My first observation was that there were more detailed Visual boards at Mitsubishi compared to other companies we had visited on the tour.

We followed that up with a Nice lunch in a typical traditional Japanese restaurant called "Kisoji"

Our second company visit of the day was at Toyota Motor Corporation.

The plant we toured had an impressive level of automation - up to 96%!!

Toyota are are aiming to be the most Environmentally Considerate Plant in the Industry.

Our third visit was to the Toyota Kaikan exhibition Space at Toyota's headquarters. Where we were able to view all of the latest models, including the new full-cell vehicle, the MIRAI.

We finished up the day with a nice dinner with all of the participants.

Sunday, April 19, 2015

Japan Lean Tour Day 3 Report

Day 3's report was submitted by Blackbelt candidate, Peter Post.

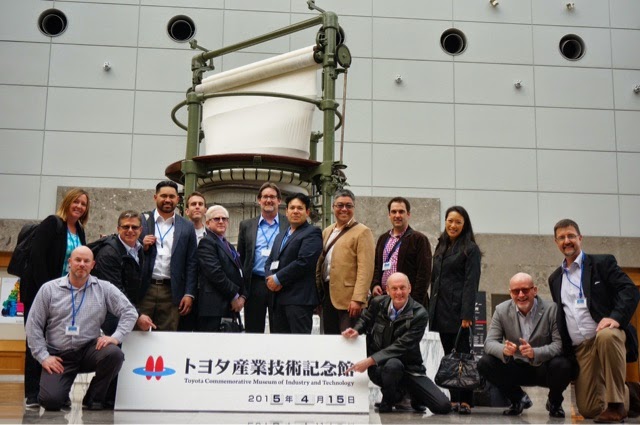

The day started with a trip to Yamaha's motorcycle plant based in the city of Iwata. Then the team made its way to the Toyota Museum of Industry and Technology.

We took a Bullet Train for 2 hrs - what an experience! That was not all, as we also did our first flash mob and almost got kicked out because one of our participant's hips were moving too fast for the Japanese security guard (joke!)

At Yamaha the team took a plant tour and was lead by a high energy tour guide. One of the items that we were introduced to was that "quality is built into the process". We saw many examples of visual management that included SOPs, a training matrix and a daily plan that could be viewed by everyone. I was very impressed with the passion of all The Yamaha staff and how diversified their product lines are.

Then it was off to the Toyota Museum to look at the history of the company. We saw many examples of an unbelievable vision of true pioneers. We went through an extensive exhibit of Toyota's textile looms and how The Toyoda family started in business.

The museum tour takes you through the journey of the Toyota up to current day. One of the highlights for me was visiting the "lean area"where exhibits explained lean tools and how they apply it to their business. To see the visual impact of their journey really solidified the idea for me that in North America we can be better with lean concepts.

When we left we did another flash mob and had locals join in!

The day started with a trip to Yamaha's motorcycle plant based in the city of Iwata. Then the team made its way to the Toyota Museum of Industry and Technology.

At Yamaha the team took a plant tour and was lead by a high energy tour guide. One of the items that we were introduced to was that "quality is built into the process". We saw many examples of visual management that included SOPs, a training matrix and a daily plan that could be viewed by everyone. I was very impressed with the passion of all The Yamaha staff and how diversified their product lines are.

Then it was off to the Toyota Museum to look at the history of the company. We saw many examples of an unbelievable vision of true pioneers. We went through an extensive exhibit of Toyota's textile looms and how The Toyoda family started in business.

The museum tour takes you through the journey of the Toyota up to current day. One of the highlights for me was visiting the "lean area"where exhibits explained lean tools and how they apply it to their business. To see the visual impact of their journey really solidified the idea for me that in North America we can be better with lean concepts.

When we left we did another flash mob and had locals join in!

Friday, April 17, 2015

Greenbelt Service Vancouver Winter 2015 Graduate

This marks the end of our 2015 Greenbelt Winter Programs.

Congratulations everyone! We appreciate all your time and effort! It is not a

big class, but we are impressed by your outstanding performance.

Applause for

our medalists:

Edin Kojic (Gold)

Janette Stoeken (Silver)

Lisa Verwolf (Bronze)

3 weeks fly in the blink of an eye, but hope this program would benefit you for the rest of your life.

For more information on upcoming Greenbelt programs, please take a look at our calendar or call/email our team at 604 264 1000/info@leansensei.com.

Tuesday, April 14, 2015

Japan Lean Tour Day 2 Report

Today the Blackbelts and Executives visited two exceptional facilities. First was Toyota L&F (Logistics & Forklift) for a very insightful tour of their logistics and material handling solutions. They demonstrated automatic storage and picking systems, a variety of automatic guided vehicles (AGV) for material movement and a voice controlled forklift with weight sensing forks to insure the operator picks the correct item and quantity.

The second tour was at the Nissan Yokohama Engine Plant were we received a quick history lesson on how the company was formed and the "DATSUN" name evolved. The first engine built at this plant was a 4 cylinder 722cc engine for the 1936 Model 15 Roadster. On display were engines covering several decades including their line of racing engines. Also displayed was a 1967 Fairlady 2000 inspired by the Broadway play "My Fair Lady". The tour through the factory was interesting in that we saw a lot of automation using robotics, machines and material handling equipment connecting each step in the process.

A solution for limited space applications was movable storage racks coupled with a forklift that operates in a 1.5 meter aisle width. Most impressive was their use of the "Dojo" to develop operator proficiency through repetitive training before placing the operator in the production environment.

The second tour was at the Nissan Yokohama Engine Plant were we received a quick history lesson on how the company was formed and the "DATSUN" name evolved. The first engine built at this plant was a 4 cylinder 722cc engine for the 1936 Model 15 Roadster. On display were engines covering several decades including their line of racing engines. Also displayed was a 1967 Fairlady 2000 inspired by the Broadway play "My Fair Lady". The tour through the factory was interesting in that we saw a lot of automation using robotics, machines and material handling equipment connecting each step in the process.

It's unanimous though, the highlight of the day (probably the trip) came in the GTR area where we met the Takumi (master craftsman Takumi Kurosawa) and his students. Takumi proudly gave us an overview of the hand built engine area followed by a demonstration of how well balanced these engines are when assembled in the GTR. He placed a bottle of water on the hood of a GTR in his shop, instructed Thomas to climb in, start it up and rev the engine up to 6000 RPM while we watched the bottle of water sit undisturbed. We then took turns revving the engine, "AMAZING" was the only way to describe it. I'm not sure who enjoyed the visit more, Takumi or the LSI group, but it was obvious Takumi is very proud of their product, yet in typical Japanese culture, equally as humble as he graciously took a group photo and provided each of us his business card.

Subscribe to:

Posts (Atom)